Rent or buy now!

Flexible rotor blade access with a spacious work place

The integrated cabin of our access system is mounted with a flexible joint so that it can rotate to follow the twist of the rotor blade. As a result, the gaps between the blade and the roof/floor of the cabin can be minimised at every point along the rotor blade. This enables optimised 360° access to the rotor blade and provides effective protection against the elements.

- Simple sealing against the effects of weather

- Maintenance cabin rotates to follow the twist of the rotor blade

- Optimised rotor blade access

- Spacious work place with workshop-like conditions for working

The service platform for all wind turbines

Optimum working conditions. Whatever the weather.

Our System terra 1.1 features a weather-proof maintenance chamber that protects you from the elements as you carry out repairs in workshop-like conditions. Fitted with integrated heating and lighting, the fully enclosable chamber provides a spacious, comfortable workplace offering a variety of storage options and good access to all sides of the rotor blade.

- Work under dry, wind-proof conditions – with a sealed roof and tarpaulins on all sides for full protection against the elements

- With heating and rain-proofing to ensure maximum comfort while working

- Integrated shelves and benches for optimised workplace ergonomics

- Lifeline all the way around the chamber for enhanced freedom of movement

- Optimized lighting of your working area

Dependable. No job too big.

The triple winch system and the integrated crosswind detection function keep the System terra 1.1 safe even in high winds and on large wind turbines and prevent the cabin from tilting over sideways. Anchoring points for attaching an overhead safety harness mean increased safety for your service engineers.

- Adaptive 3-winch system

- Crosswind detection function automatically initiates safety procedures

- Frame swivels to position the chamber around the blade tip at the push of a button

- Automatic slope correction function keeps the chamber level at all times

- Operator anchoring points available on the cabin ceiling

- Integrated uninterruptible power supply (battery) ensures the safe return of the chamber to ground level even if a power outage occurs

- Frame rolls safely over joints between segments of hybrid towers

- Lighting for the working area and for the entire upward/downward travel zone

- Tailored lighting concept

Tilt stability against horizontal and vertical overturning

Positioning the chamber around the blade tip

Remote control for maximum safety and clarity

Our user-friendly radio remote control and the touchscreen on the control cabinet ensure safe, intuitive system operation. Key parameters are monitored continuously with the aid of modern sensors and displayed to the user in a clear, logical way.

- Touchscreen for integrated system monitoring and operation

- Radio remote control for simple, intuitive operation

- Safety alerts communicated acoustically and visually

- Remote monitoring and diagnostics

Make full use of manpower and equipment

Repairs are possible around the clock thanks to the illumination of the maintenance chamber and the surrounding area with the aid of an integrated lighting system. Additional lighting kits are also available for customers with specific lighting requirements.

- Interior lighting for optimized, consistent working conditions

- Exterior lighting for the monitoring of smooth system operation

- Lighting enables round-the-clock shift work

Ready to use. Simple to transport.

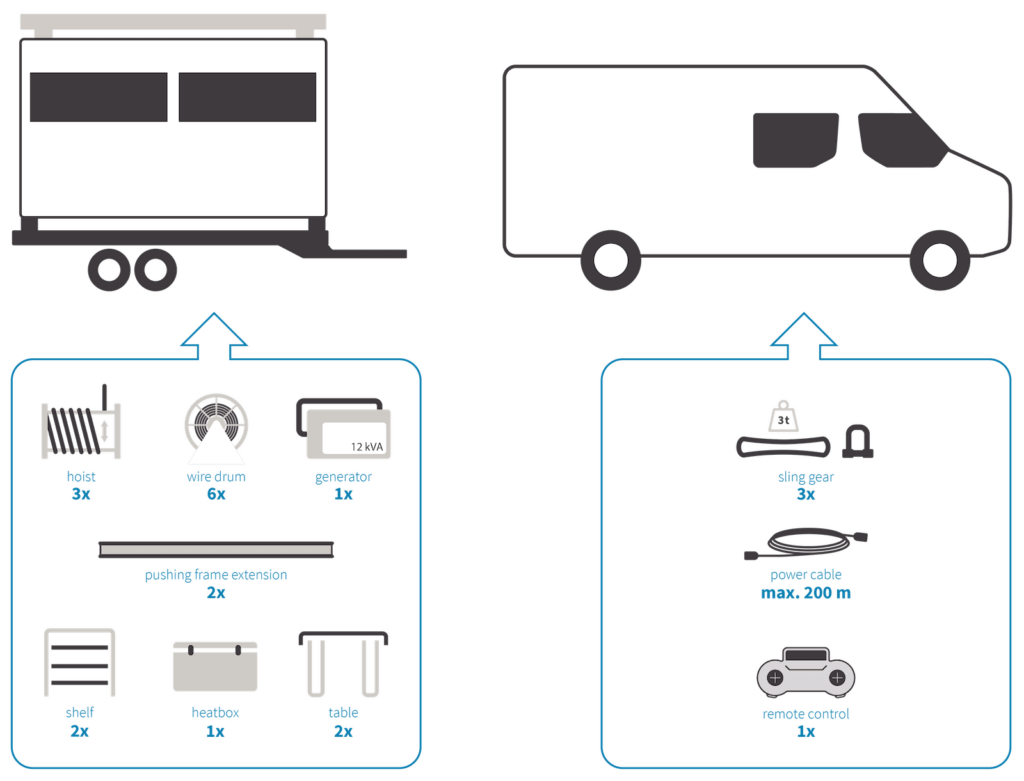

Our System terra 1.1 is designed for efficient assembly and disassembly, with a single locking mechanism used to fix the maintenance chamber onto a specially developed 3.5 t trailer for transportation. The trailer also comes fitted with winches for the raising and lowering of the chamber. An integrated generator is available on request. A range of optional extras make it possible to adapt the maintenance system to your specific requirements.

- Twist-lock system for the rapid attachment of the chamber onto the trailer

- Simple, efficient assembly and disassembly

- Intuitive operation using a wireless remote control

- Optional extras include an infrared heater, lighting kit, storage system, temperature-controlled chemical storage box and hand winch

- Almost all the accessory parts are transported on the trailer, so no additional loads are placed on the load capacity of the towing vehicle

Transporting extra Equipment with the trailer

Technical information

System terra

Dependable. No job too big.

Sealing system/

rain-proofing

Independently retractable tarpaulins on all 4 sides

Full sealing of the roof

Winching speed

9 m/min

Winches/emergency arresting devices

Tirak / Blocstops

Max. rotor blade dimensions

4.30 m x 2.20 m

Max. distance between tower and blade tip

15.20 mr

Max. wind turbine height

180 m (contact us to discuss taller turbines)

Max. wind speed

14 m/s

Monitoring

Remote maintenance of the control system, GPS sensor

Ready to use. Simple to transport.

Dimensions when in transport mode

9,00 m x 2,55 m x 3,90 m

Tare weight

1,750 kg

Loading capacity

400 kg (max. 3 people)

Transport

Specially built tandem trailer

Accessories

System terra

Optimum working conditions. Whatever the weather.

Heating

4 x 2,000 W infrared heaters

Air extraction

Festool (for use when the chamber is closed)

Lighting kit

For use on the platform and on the ground

Storage system

2 mobile benches, 2 integrated shelves

Generator (with exhaust hose)

12 kVA diesel generator

Hand winch (incl. 200 m of cable

Goracon G-smartrac 150 vario

Temperature-controlled chemical storage box

600 mm x 300 mm x 300 mm (LxBxH)

Temperature range: +15 °C to +32 °C

Boost your planning security and profitability

Same team. Enhanced maintenance performance.

Our System terra 1.1 is equipped with integrated lighting that enables you to also carry out maintenance work at dawn and dusk. Whether you opt to extend your daily maintenance hours or work in round-the-clock shifts, the System terra 1.1 makes it possible for you to repair faulty rotor blades throughout the year.

Choose our System terra 1.1 to minimise downtime and ensure compliance with turbine availability guarantees.

Increase your potential number of operating hours per day

Reduce the downtime of wind turbines and maintenance systems alike

- CURRENT

- 1 SHIFT SYSTEM

- 2 SHIFT SYSTEM

- 3 SHIFT SYSTEM